Polyacrylamide (cpolyacrylamids) is abbreviated as PAM, which is divided into anion (HPAM), cation (CPAM), and non-ionic (NPAM) is a linear polymer, which is one of the most widely used varieties of water-soluble polymer compounds. Polyacrylamide and its derivatives can be used as effective flocculants, thickeners, paper enhancers and liquid drag reducers, etc., and are widely used in water treatment, papermaking, petroleum, coal, mining and metallurgy, geology, light textiles, etc. , Construction and other industrial sectors.

Polyacrylamide (cpolyacrylamids) is abbreviated as PAM, which is divided into anion (HPAM), cation (CPAM), and non-ionic (NPAM) is a linear polymer, which is one of the most widely used varieties of water-soluble polymer compounds. Polyacrylamide and its derivatives can be used as effective flocculants, thickeners, paper enhancers and liquid drag reducers, etc., and are widely used in water treatment, papermaking, petroleum, coal, mining and metallurgy, geology, light textiles, etc. , Construction and other industrial sectors.

PAM physical properties and usage characteristics:

1. Physical properties: molecular formula (CH2CHCONH2)r

PAM is a linear polymer, it is easily soluble in water, almost insoluble in benzene, ethylbenzene, esters, acetone, etc. General organic solvent, its aqueous solution is almost transparent viscous liquid, it is non-dangerous, non-toxic, non-corrosive, solid PAM has hygroscopicity, and the hygroscopicity increases with the increase of ionicity, PAM has good thermal stability; It has good stability at 100°C, but it is easy to decompose to produce nitrogen when it is above 150°C. It will undergo imidization between molecules and is insoluble in water. The density (g) ml is 1.302 at 23°C. With a glass transition temperature of 153°C, PAM exhibits non-Newtonian fluidity under stress.

2. Use characteristics

Flocculation: PAM can neutralize suspended matter through electricity, bridging adsorption, and flocculating.

Adhesiveness: It can play the role of adhesion through mechanical, physical and chemical action.

Resistance reduction: PAM can effectively reduce the frictional resistance of the fluid. Adding a small amount of PAM in the water can reduce the resistance by 50-80%.

Thickening: PAM has a thickening effect under neutral and acidic conditions. When the PH value is above 10°C, PAM is easily hydrolyzed and has a semi-network structure, the thickening will be more obvious.

3. Introduction to the principle of PAM:

The principle of flocculation: When PAM is used for flocculation, it is related to the surface properties of the flocculated species, especially the dynamic potential, viscosity, turbidity and the pH value of the suspension. The dynamic potential on the surface of the particles is the reason for the inhibition of particle aggregation. Surface charge is added On the contrary, PAM can condense by lowering its rapid potential.

Adsorption bridging: PAM molecular chains are fixed on the surface of different particles, and polymer bridges are formed between the particles, so that the particles form aggregates and settle.

Surface adsorption: various adsorption of polar group particles on PAM molecules.

Reinforcing effect: PAM molecular chain and dispersed phase link the dispersed phase together through various mechanical, physical, chemical and other functions, forming a network, thereby playing a reinforcing effect.

The main purpose of polyacrylamide: polyacrylamide (PAM) has high molecular weight, good water solubility, adjustable molecular weight, and can introduce various ionic groups to obtain specific properties. Low molecular weight is an effective modifier or stabilizer for dispersion materials, and high molecular weight is an important flocculant.

It can make a hydrophilic and water-insoluble gel, which has good adhesion to the surface of many groups and dissolved substances. Due to the above properties, PAM is widely used in fields such as flocculation, thickening, drag reduction, gelation, adhesion, and scale inhibition.

4. Main Technical index

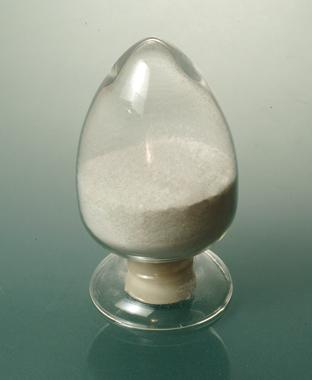

Appearance: White particles

Solid content: ≥88%

Molecular weight: 6-20 million

Anions: Ionity: 20%-30% (adjustable) Cation: Ionity: 5--60%

Non-ion: Ionity 1-4%

| species |

Anionic type

|

Cationic type

|

Non-ionic type

|

Zwitterionic Type | |||

| Appearance |

White particle

|

White particle

|

White particle

|

White particle

|

|||

| Solid content,% |

≥90

|

≥90

|

≥90

|

≥90

|

|||

| Molecular weight. 10K |

300-2000

|

300-1500

|

300-1500

|

300-1500

|

|||

| Ionity,% |

20-30

|

5-60

|

0-3

|

Any ratio

|

|||

| Insolubles% |

≤0.1

|

≤0.1

|

≤0.1

|

≤0.1

|

|||

| Dissolution time (min) |

≤40

|

≤90

|

≤60

|

≤90

|

|||

| Uses | Weak anionic | Solid-liquid separation under neutral and weak acid conditions: industrial wastewater such as papermaking, mineral processing, secondary treatment of domestic sewage from smelting | Weak Cationic | Sludge dewatering of pulp in paper mills, industrial dewatering | Solid-liquid separation under neutral, strong acid, and strong alkaline conditions: 1. Paper and pulp wastewater 2. Mineral processing and metal smelting process wastewater. 3. Iron and steel plant wastewater 4. Other industrial wastewater |

Other than Example |

Difficult to air float sewage treatment, difficult to treat biochemical sludge, dead mud, dewatering of sedimentation |

| Medium anionic | Solid-liquid separation and beneficiation under weak acid and weak alkali conditions, coal mines, metal processing, chemical plants, food, textiles, printing and dyeing, sugar making, quoting water and other industrial waste water, oil field flooding | Medium Cationic | Organic sludge dewatering in domestic sewage treatment plants and industrial sewage treatment plants sludge dewatering in paper mills, sludge dewatering in breweries, pharmaceutical plants, etc. | anionic>cationic | Three oilfield mining: industrial sewage treatment | ||

| Strong anionic | Solid-liquid separation under weak alkaline conditions: metal smelting, beneficiation, aluminum ore and other mining additives | Strong Cationic | Oily sewage treatment, domestic sewage treatment, fecal sewage treatment, chemical fiber and other industrial sewage treatment | anionic| Dewatering treatment of difficult-to-dehydrate organic sludge, organic sludge treatment in domestic sewage treatment plants, treatment of biochemical polluted sludge in paper mills |

| ||